CAPA: The basis for continuous improvement

CAPA (Corrective and Preventive Action) Management is an essential part of continuous improvement. Because it ensures temporary correction of bottlenecks in acute problems, as well as prevention of recurrence.

Performing corrective or preventive actions (CAPA Management, in other words) is required when recording audits, incidents or deviations, for example. However, managing tasks and actions as well as monitoring progress is often a challenge using only loose lists, Excel and e-mail.

Centralizing tasks and actions in a single CAPA registry has many advantages. With LeanForms, all actions, regardless of source, are managed centrally. There is always visibility into what triggered a task and the number and status of actions at the source are visible.

This not only saves time, but also prevents things from being forgotten.

Flexibility and simplicity

Plotting actions is flexible and easy with LeanForms. You can investigate the actual cause (Root Cause), perform risk analysis or perform a Management of Change (MoC). Follow-up is variable and depending on various conditions, the task is automatically forwarded to the right person or department within your organization.

CAPA: Monitoring effectiveness of actions

A crucial part of CAPA is monitoring the effectiveness of actions. LeanForms handles and records this efficiently. You have real-time visibility into tasks and actions that were not effective and what follow-up actions were taken. This keeps the process focused on improving results.

With LeanForms, you always have a clear presentation of the actions. This allows you to easily monitor progress and make decisions to improve the process.

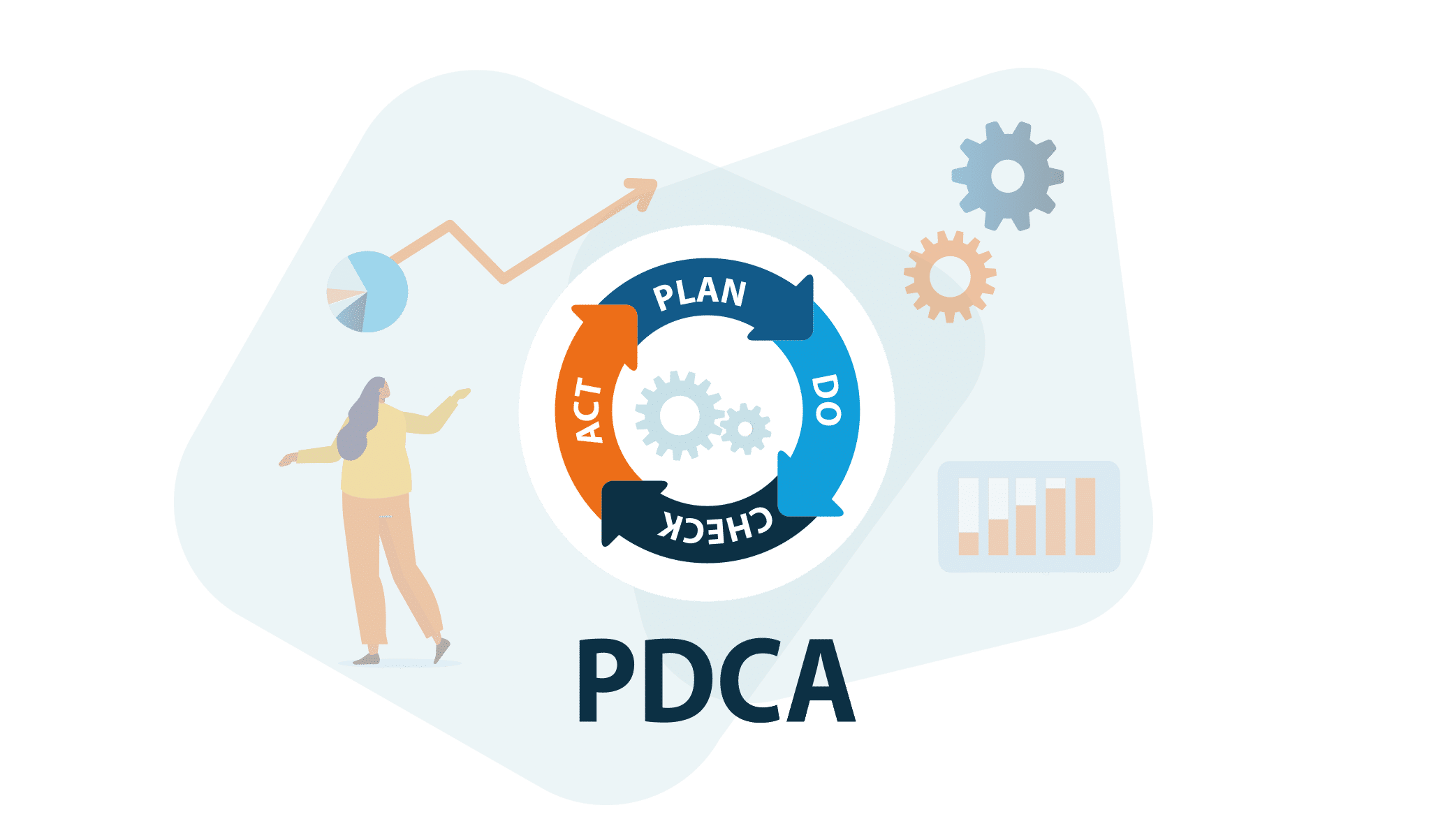

How PDCA helps with effective CAPA Management

PDCA (Plan-Do-Check-Act) is a continuous improvement approach that can support the effectiveness of CAPA processes by focusing on continuously improving the effectiveness of actions.

You can use PDCA in the following way:

- Plan: Identify the problem and plan the corrective or preventive action that works best.

- Do: Perform the action and collect data on the results.

- Check: Evaluate the effectiveness of the action based on the data collected and find out if it solves your problem.

- Act: Standardize the action if it proves effective or repeat the cycle if improvement is needed.

Getting started with CAPA Management?

We like to show you how we can help manage and integrate your CAPA processes to continuously improve!

Want to know more? Get in touch

Do you have questions or are you curious how LeanForms can support your organization? We are ready to answer all your questions! Get instant specialized advice on the best solution for your specific situation.

Related items

RI&E: From obligation to dynamic tool

Preparing a risk inventory and evaluation (RI&E) has been a legal requirement for some time, but despite this, many companies struggle to set up their RI&E correctly.

Business continuity management

business continuity management sounds like a “far from my bed show” to many entrepreneurs. Or they prefer not to dwell on it.

Performance indicators, to measure is to know

Performance indicators are indispensable for organizations managing for quality. And quality can be expressed in many ways. A good product, safe execution of work, or good accounts payable management.

Prospective risk analysis, smart execution one less worry!

With a prospective risk analysis, you analyze risks. The power of a good PRI is in its integration with daily activities.