PDCA

What is PDCA?

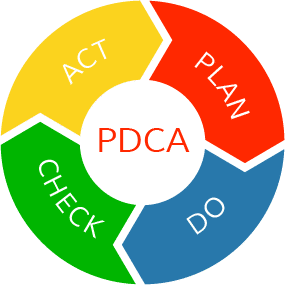

PDCA is a powerful philosophy for implementing continuous improvement. By closely following the four steps of the PDCA cycle (Deming’s circle of quality), you address problems, questions and opportunities in a thoughtful, structured way.

A brief explanation of the four steps: With ‘Plan’ you look at current work and design a plan for improving this work. With ‘Do’ you carry out the planned improvement in a controlled trial. Measure the result of the improvement and compare it with the original situation with ‘Check’. Finally, with ‘Act’ you make adjustments based on the results found with ‘Check’.

Continuous improvement with LeanForms and PDCA cycle

LeanForms, the powerful digital forms tool, is an ideal partner for organizations striving for continuous improvement. By integrating Lean principles and the PDCA cycle, LeanForms provides a structured approach to optimizing processes. Users can efficiently plan, execute, monitor and make adjustments, creating an iterative cycle of improvement.

Also read the blog article “PDCA, a goal-oriented approach.

Related items

Getting a grip on quality and safety: from capturing to improving

We often already record. But improving requires more than just recording.

Customer speaking: az Vesalius

az Vesalius is a regional hospital in South Limburg, Belgium, with branches in Tongeren and Bilzen. The hospital has a wide range of specialties and provides care to diverse patient groups. In 2017, they received the NIAZ quality label, which stands for expert care, safety and improvement-oriented corporate culture.

Customer speaks: Daiwa House

Daiwa House Modular Europe (DHME) is Europe’s largest construction company specializing in modular construction. What once began as Jan Snel in 1960 grew into a leading construction company that is part of Japan’s Daiwa House Group, the world’s largest industrial builder. With four production locations in the Netherlands and about 700 employees in Europe, DHME delivers complete housing solutions suitable for at least 80 to 100 years of use: From family homes and student housing to care and accommodation projects. From the ultramodern robotized factory in Montfoort, thousands of new housing modules roll off the assembly line each year.

Advanced workflows step by step

Digitization does not stop at replacing paper forms with a digital alternative. The real gain comes when processes become smarter. Workflows play a key role in this: By setting up digital forms intelligently, the system automatically streamlines the follow-up based on the answers. This gives your organization grip, speed and peace of mind and makes digitization work for you.

Want to know more? Get in touch

Do you have questions or are you curious how LeanForms can support your organization? We are ready to answer all your questions! Get instant specialized advice on the best solution for your specific situation.

Tailor made solutions

No standard approach, but customized solutions. LeanForms adapts to your processes, not the other way around. Digitize smarter, work more efficiently and maintain full control, without IT complexity. From smart forms to automated workflows: We provide a solution that really works for your organization….