PDCA, a goal-oriented approach

Secure the implementation of improvements in every business process.

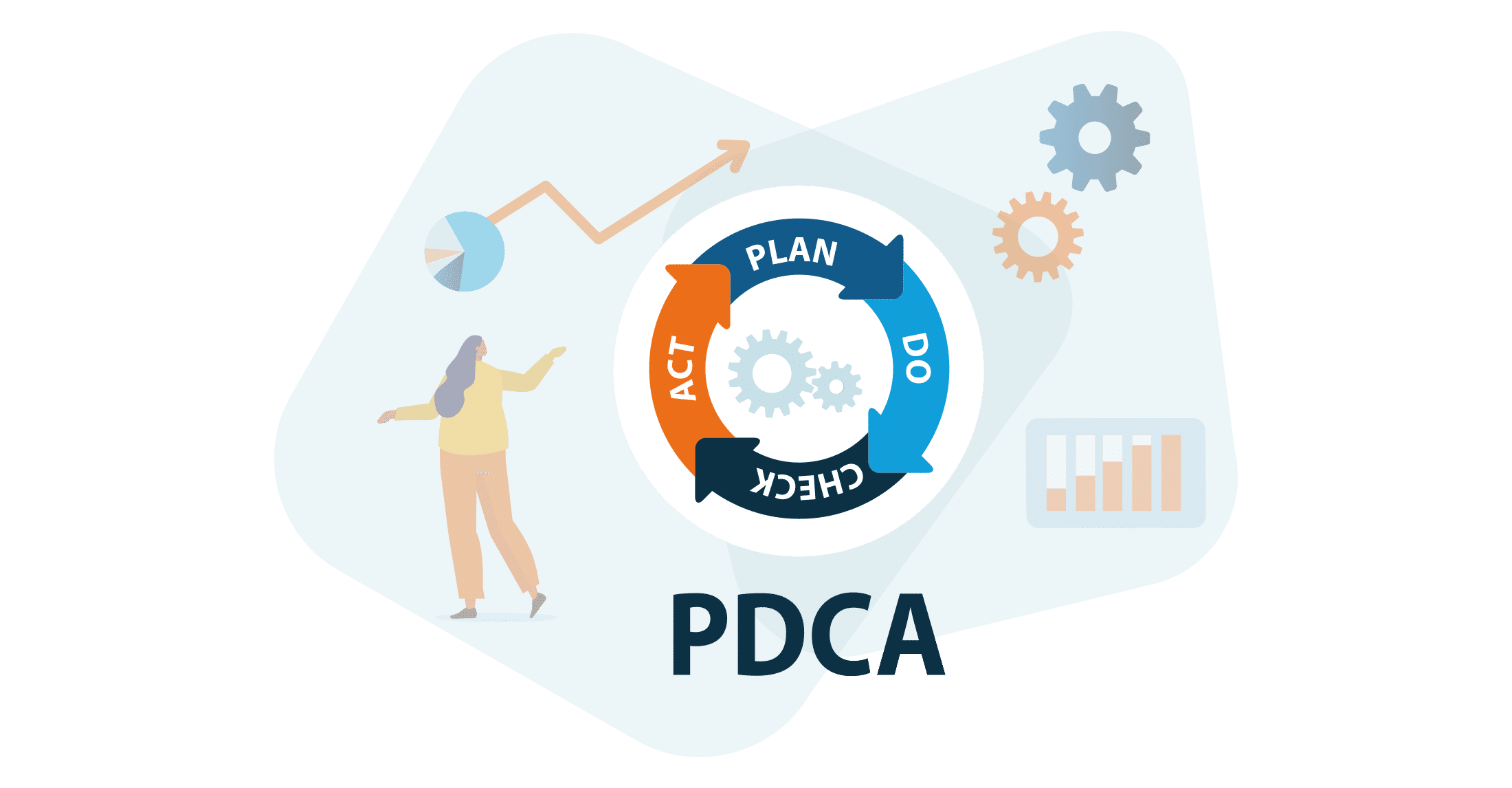

PDCA, quality management in 4 steps

The PDCA cycle is a well-known tool for continuous improvement, quality management and problem solving. The cycle was developed by William Edwards Deming and is therefore also known as Deming’s Quality Circle(SixSigma.com)

ISO certifications and audits test this cycle extensively. This allows organizations to see if they are learning from their mistakes and continuously improving operations For management, high efficiency of the organization and resources is ultimately the goal. Yet a lot of organizations struggle to implement PDCA successfully. In this blog, we elaborate on this and provide tips for successful PDCA implementation.

The ‘Plan Delay Cancel Apologize’ syndrome

Proper implementation of the PDCA cycle stands and falls with proper planning in an organization. If one is aware of the need for continuous improvement, one should also make time for this. A well-known pitfall is that many plans and actions are initiated within an organization without naming them SMART. But also that no space or resources are set aside to work on them. As if naming things will solve the problems by itself. The result is that people put things off and the plans eventually fall between two stools. Until history repeats and repeats itself.

PDCA also requires leadership

Obviously, managers must be aware of their role. The success of PDCA requires commitment and support from managers. This applies not only to time and resources but most certainly also in monitoring progress and results in improvement processes. Managers must therefore have a good overview of all planned activities within the organization. Digital tools and periodic consultation structures can help tremendously here, but it is ultimately people who make the difference.

To improve is to change

To avoid unwanted side effects when implementing improvements in organization and business processes, changes should be implemented in a controlled manner. A good management of change process is therefore always part of the PDCA improvement cycle. Here it is important that all stakeholders are informed in a timely and complete manner about the proposed change. Proper information leads to proper acceptance and implementation of the change.

Tips for PDCA implementation

- Good planning and SMART objectives for improvement proposals are essential. Especially in the beginning, limit the number of projects to ensure that there is enough attention and capacity available in the organization for this.

- Digitize the PDCA process so that all information can be centralized in one location. This also enables better oversight of progress and outstanding actions. A smart digital system can fully automate action management. An additional benefit of digitizing improvement projects is building a digital archive. With clever design, one builds a digital knowledge archive.

- Applying visual management tools such as dashboards and infographics can help to clearly present progress and results of improvement projects. By providing visual insight into the status of PDCA initiatives, employees and management can quickly see where they stand and what actions are still needed. This approach increases transparency and engagement within the organization.

- Share realized successes with employees in the organization. They then see that something has really happened with a problem they may have experienced themselves.LeanForms can support organizations in implementing PDCA by providing customized digital solutions that automate and centralize the entire PDCA process. With user-friendly interfaces and extensive reporting capabilities, LeanForms ensures that companies have better overview and control over their improvement projects.

Want to know more about digitizing following the PDCA method? We are happy to help you get started, request a no-obligation demo.

Want to know more? Get in touch

Do you have questions or are you curious how LeanForms can support your organization? We are ready to answer all your questions! Get instant specialized advice on the best solution for your specific situation.

Related items

RI&E: From obligation to dynamic tool

Preparing a risk inventory and evaluation (RI&E) has been a legal requirement for some time, but despite this, many companies struggle to set up their RI&E correctly.

Business continuity management

business continuity management sounds like a “far from my bed show” to many entrepreneurs. Or they prefer not to dwell on it.

Performance indicators, to measure is to know

Performance indicators are indispensable for organizations managing for quality. And quality can be expressed in many ways. A good product, safe execution of work, or good accounts payable management.

Prospective risk analysis, smart execution one less worry!

With a prospective risk analysis, you analyze risks. The power of a good PRI is in its integration with daily activities.