RI&E: From obligation to dynamic tool

A Risk Inventory and Evaluation (RI&E) has been a legal requirement for companies for many years, but is often seen as a static document that serves mainly to comply with regulations. But what if you could turn it into a powerful steering tool for improvements within your organization? In this blog you will read how to use an RI&E strategically, link it to quality management, and use digital innovation to create a dynamic instrument for improving and continuously optimizing business processes.

The RI&E as a foundation for risk management

Companies with more than 25 employees are required to have their RI&E reviewed by a certified core expert, while smaller companies can use a recognized industry RI&E. Yet in practice, many organizations draw up their RI&E but then fail to actively use it. As a result, risks remain unresolved and opportunities for improvement are missed.

By using the RI&E as a dynamic instrument, companies can not only identify risks, but also structurally control and reduce them. This leads to fewer incidents, a safer working environment and increased job satisfaction among employees. Moreover, a well-managed RI&E can contribute to quality assurance and standardization within the organization.

Standardization as an opportunity, not a burden

Many companies view standards such as ISO 45001 (occupational health and safety) or ISO 9001 (quality management) as an obligation. But when standards are used strategically, they can actually contribute to a culture of continuous improvement. The High Level Structure (HLS) of ISO standards provides a framework that makes it easier to integrate different standards and link risk management to quality management.

The High Level Structure (HLS) is a guideline for the development of new ISO management system standards that largely harmonizes their structure and requirements. ISO’s goal with the HLS is to ensure uniform use of core texts, terms and definitions. Above all, the common core requirements promote the integration of different systems in an organization. (Source: DQSglobal)

By deploying smart digital solutions, standardization not only becomes more workable, but also a driver of innovation. Information systems can help identify risks, improve processes and make audits more efficient.

Digital innovation as an engine for a dynamic RI&E

Modern software solutions make it possible to link risk management, quality management and standards. By setting up a dynamic RI&E with digital tools such as LeanForms, companies can:

- Assign action holders and set deadlines so that tasks do not get left behind.

- Send automatic reminders, ensuring actions are actually followed up.

- Generate real-time reports, giving management immediate insight into outstanding risks and areas for improvement.

- Integrate FMEA (Failure Mode and Effects Analysis) to analyze and manage risks in a structured manner.

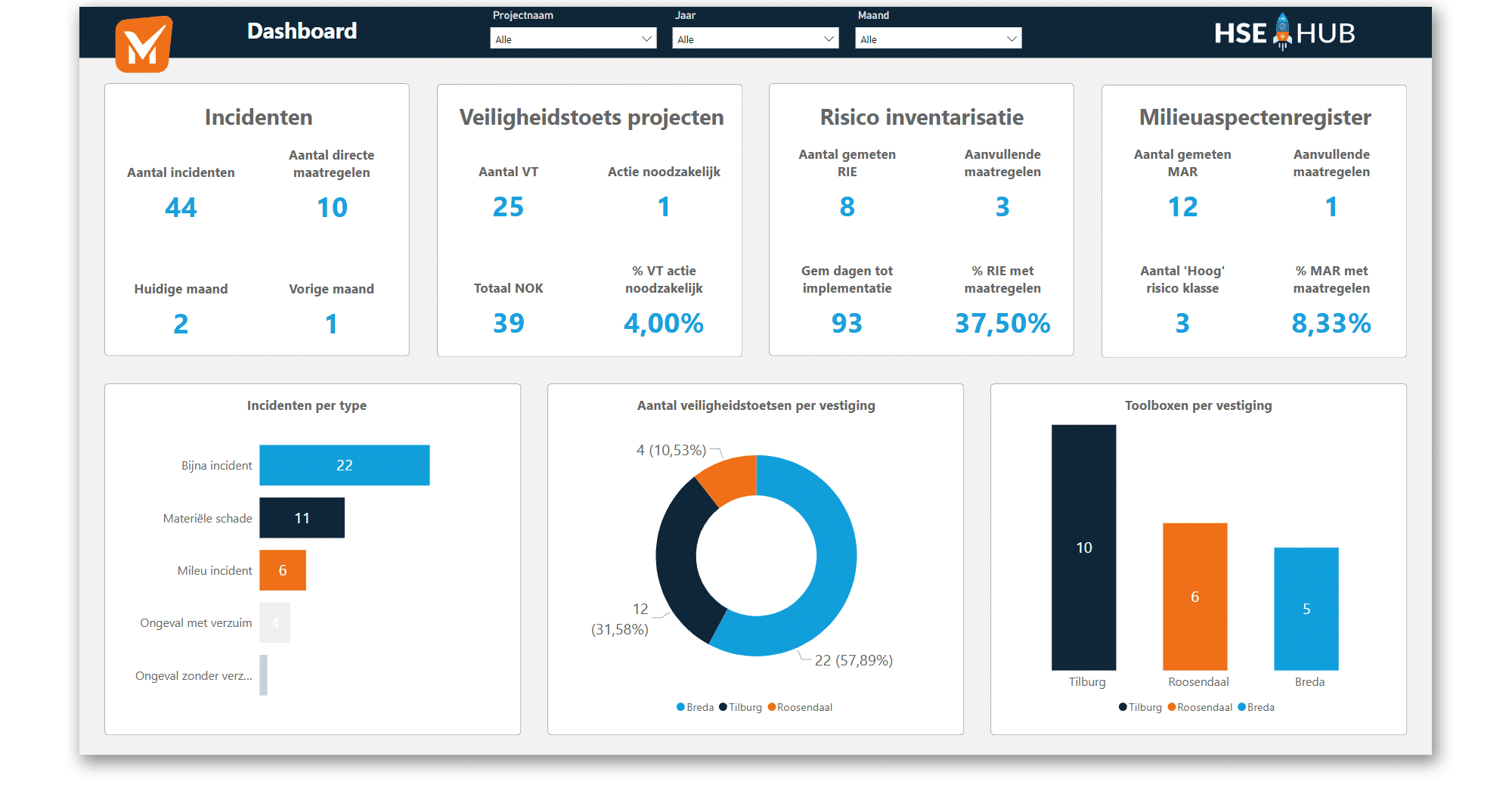

A good practical example is the implementation of the HSE HUB at an organization that was struggling with fragmented HSE processes. By moving to a central digital system, all HSE records were managed more efficiently, leading to real-time monitoring, proactive risk management and a strengthened safety culture within the organization. This shows how digitization can help make an RI&E not only more workable, but also more strategic.

By managing risk inventories and improvement measures digitally, the RI&E no longer becomes a document that disappears into a drawer, but a strategic instrument that actively contributes to continuous improvement.

The benefits of an integrated approach

Combining risk management, quality management and standards intelligently produces immediate benefits:

- Better compliance with laws and regulations, without unnecessary administrative burdens.

- More efficient process management by systematically addressing risks and areas for improvement.

- Improved safety and quality, leading to fewer incidents and higher customer satisfaction.

- Cost efficiency by reducing unexpected disruptions and internal problems.

Make your RI&E a lively and strategic tool

Would you like support in setting up an RI&E that really lives within your organization? Then contact us for a no-obligation introductory meeting with one of our consultants.

Want to know more? Get in touch

Do you have questions or are you curious how LeanForms can support your organization? We are ready to answer all your questions! Get instant specialized advice on the best solution for your specific situation.

Related items

Getting a grip on quality and safety: from capturing to improving

We often already record. But improving requires more than just recording.

Advanced workflows step by step

Digitization does not stop at replacing paper forms with a digital alternative. The real gain comes when processes become smarter. Workflows play a key role in this: By setting up digital forms intelligently, the system automatically streamlines the follow-up based on the answers. This gives your organization grip, speed and peace of mind and makes digitization work for you.

Guide to optimizing processes

Process optimization as a continuous improvement process. Process optimization is a continuous improvement process that not every organization is proactively working on yet.

The digital workplace, organizing with 5S

One of the methods within LEAN is the 5S Workplace Inspections, better known as 5S. It is often used to establish and maintain a tidy and orderly physical workplace.